STAMP-TECH

Stamp-Tech, Precision Stampers was incorporated in 2000 starting a new millennium in providing quality precision stampings to customers who wanted parts on time that would meet specifications to insure a quality product. We are strategically located in central North Carolina just outside of Raleigh and the Research Triangle Park. Our experienced toolmakers work hard to ensure that our customers come first. Our objective is to offer our customers a precision stamping service based on consistency and quality of each and every part produced in our facility. Presses up to 60 tons equipped with automated controls along with video measuring equipment and comparators are used to measure piece parts during the manufacturing process. Our goal is to produce accurate parts with every press stroke.

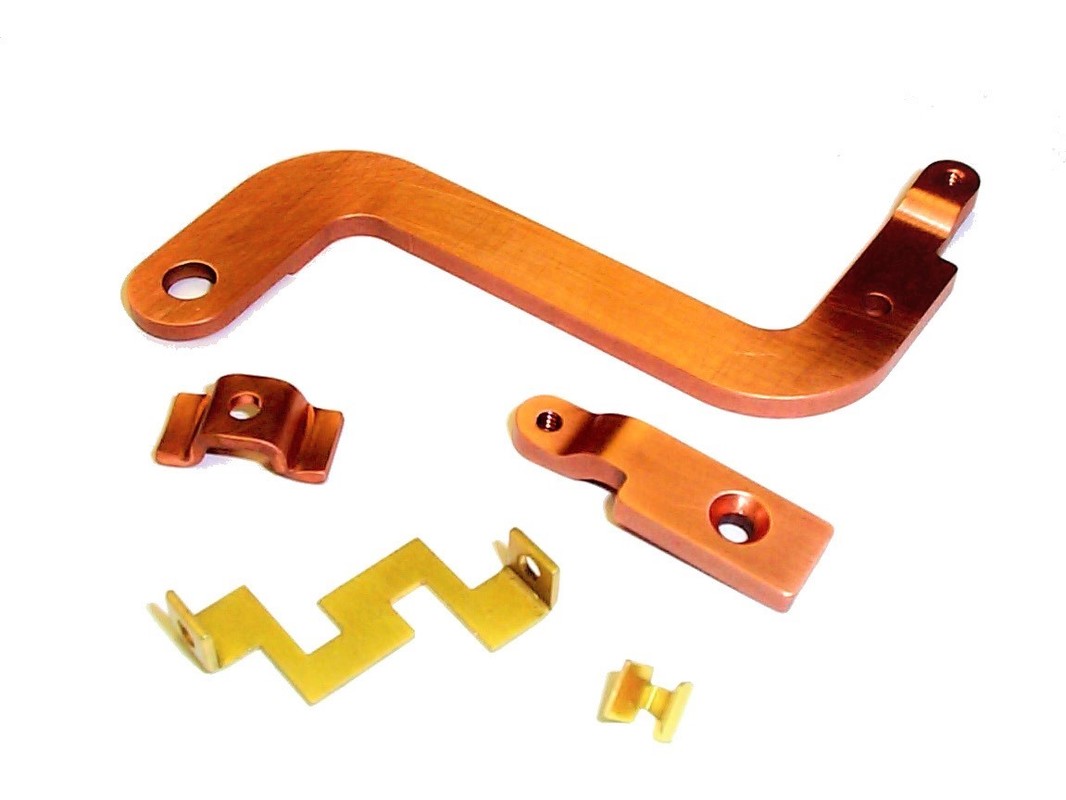

Stamp-Tech ships components to customers within the US, Costa Rica, Mexico and China. We offer our customers a wide range of capabilities including stamping, assembly, drawing, coining, and tapping with sources for painting, powder coating and electroplating.

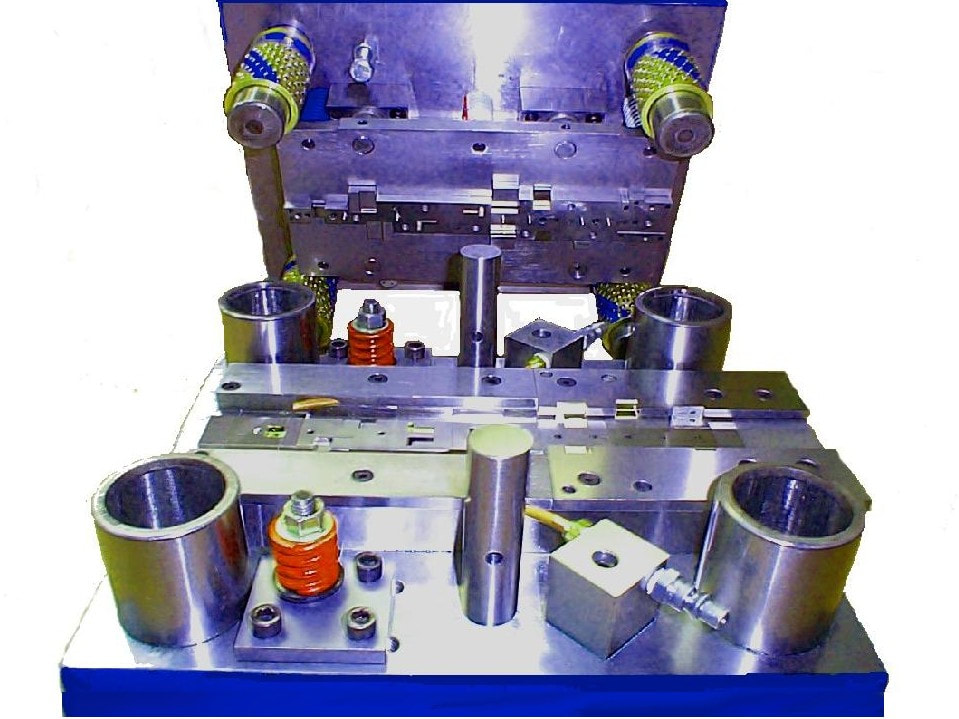

Stamp-Tech offers the abilities to manufacture tools through extensive knowledge and skilled craftsmanship of experienced toolmakers. Our dies our designed, manufactured and maintained within our facility. Routine and preventative maintenance is performed on our tools to maintain a high level of accuracy and consistency. New tooling can also be designed, built, debugged and sampled before shipment to the customer.

Stamp-Tech offers the ability to produce Engineering samples for testing and evaluation. This may include a new product design or design change on an existing component. We also offer short run tooling to produce stamped parts that are only needed in limited quantities. This service is an alternative to provide lower costs, reduce lead-times and offer greater flexibility on new products. We would appreciate the opportunity to quote on your metal stamping requirements.

Stamp-Tech ships components to customers within the US, Costa Rica, Mexico and China. We offer our customers a wide range of capabilities including stamping, assembly, drawing, coining, and tapping with sources for painting, powder coating and electroplating.

Stamp-Tech offers the abilities to manufacture tools through extensive knowledge and skilled craftsmanship of experienced toolmakers. Our dies our designed, manufactured and maintained within our facility. Routine and preventative maintenance is performed on our tools to maintain a high level of accuracy and consistency. New tooling can also be designed, built, debugged and sampled before shipment to the customer.

Stamp-Tech offers the ability to produce Engineering samples for testing and evaluation. This may include a new product design or design change on an existing component. We also offer short run tooling to produce stamped parts that are only needed in limited quantities. This service is an alternative to provide lower costs, reduce lead-times and offer greater flexibility on new products. We would appreciate the opportunity to quote on your metal stamping requirements.

We utilize the most modern inspection techniques and equipment to assure our customers the quality of their metal stamping products and other services we have to offer. We will gladly welcome any on-site audit so that you can have peace of mind to know we can be a perferred vendor for you.